Services Offered – What We Do

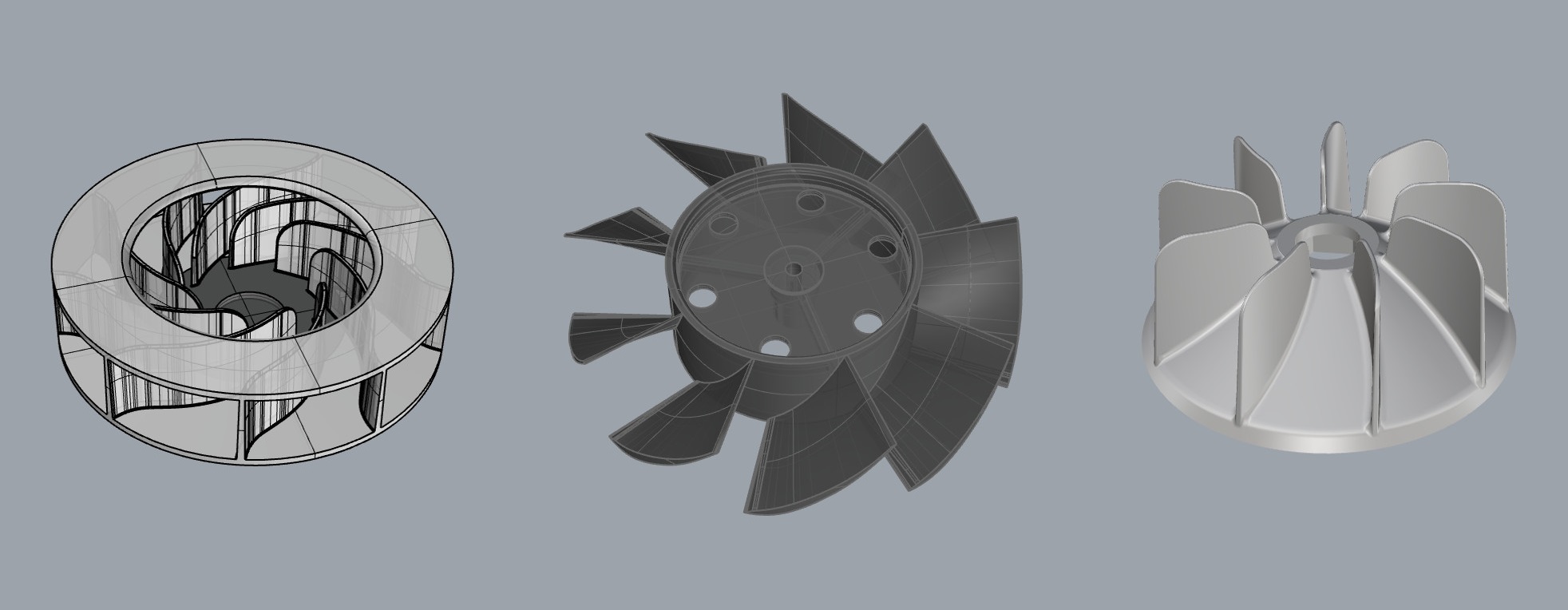

DI MAURO - Fan Molding

We grant 360° consultancy on the project, starting already from the initial stages, by providing numerous different services. Thanks also to the consolidated synergies developed over the years with our technical partners.

ENGINEERING

MATERIAL CHOICE

PLASTIC MOULDING

our Core Business is the injection molding of thermoplastic materials. We are committed to offering you high-quality products “MADE IN ITALY” that fulfil your requests and exceed your expectations

We are committed to offering you quality “made in italy ” products that reflect your requirements and exceed your expectations

PROTOTYPING

MOLD CONSTRUCTION

HUMIDIFICATION

Research and development

DI MAURO Ventole is able to offer research and development services thanks to the Fan Systems Test Bench available within its laboratory.

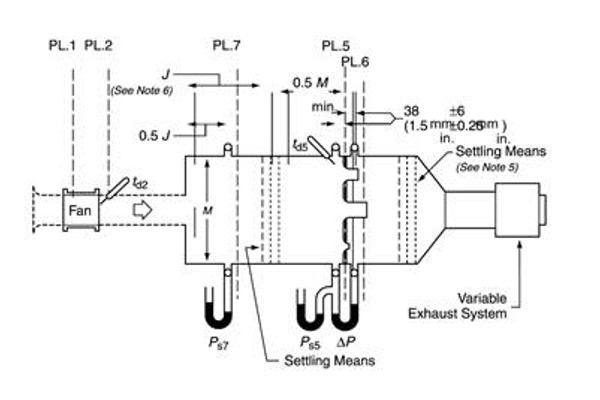

The bench allows the execution of tests in accordance with the international standards AMCA 210-16 and ISO 5801-2017. In particular, the bench refers to the AMCA 210-16 configuration identified as Outlet chamber Setup — Multiple Nozzles In Chamber

Modello di riferimento del Banco Prova a disposizione (AMCA 210-16)

The chamber has a square section of 350 x 350 mm and an overall length of 2000 mm. The diameters of the nozzles available are 20 mm, 31 mm, 45 mm and 65 mm.

The rich array of sensors present allows for the detection and determination in real time of:

– Pressure

– Flow rate

– Temperature

– RPM

– Electrical power consumption, voltage and current

– Noise level

and, in addition, to set the supply voltage

The test data are acquired in real time (with acquisition frequencies that can go beyond 100 Hz) and, if necessary, also for a long time interval in order to allow, in addition to the instantaneous characterization of the performance, also an evaluation of its consistency.

The possibility of quickly producing the necessary design elements allows each ventilation system to be connected to the test bench, eliminating all possible causes of inlet leaks, thus ensuring the reliability of the data obtained. The fans can therefore be tested in different configurations, for example both stand-alone and assembled inside a finished product (such as a hair dryer).

Experimental data can be provided both in a synthetic and detailed form, with proposals for possible approaches for data analysis from which, thanks to the skills acquired, it will be possible to offer solutions for product improvement.

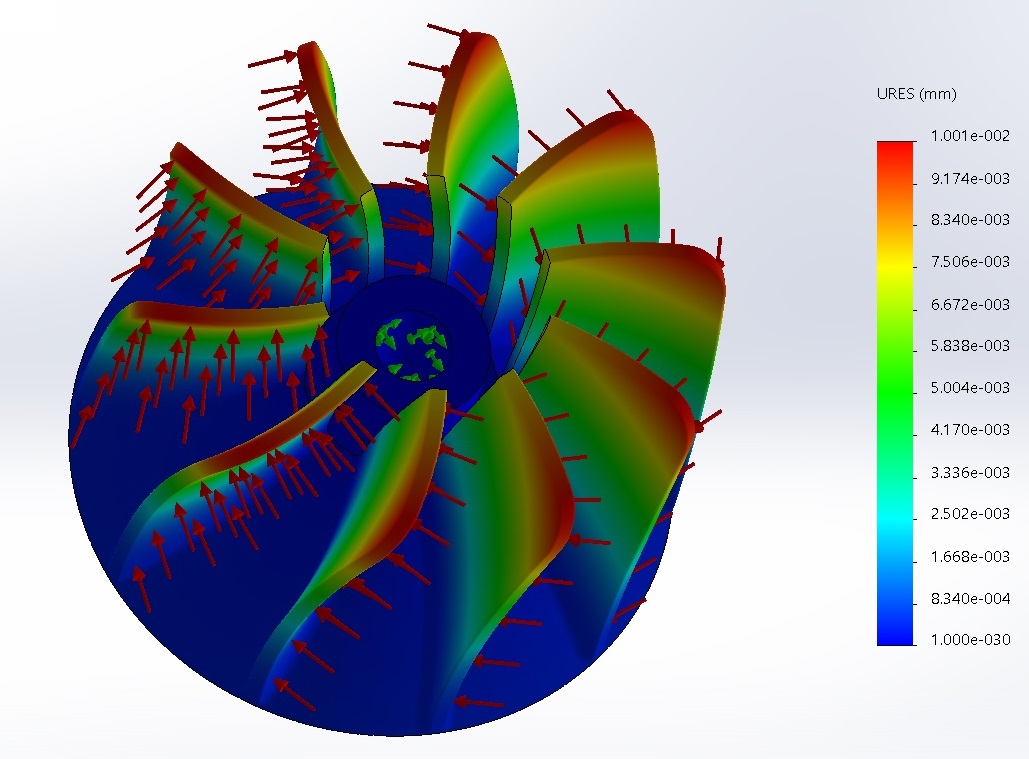

FEM and CFD Analysis

Thanks to our collaborators we are able to develop:

FEM (Finite Element Method) Analysis:

Ability to perform complex structural analyses to evaluate the resistance and deformation of materials.

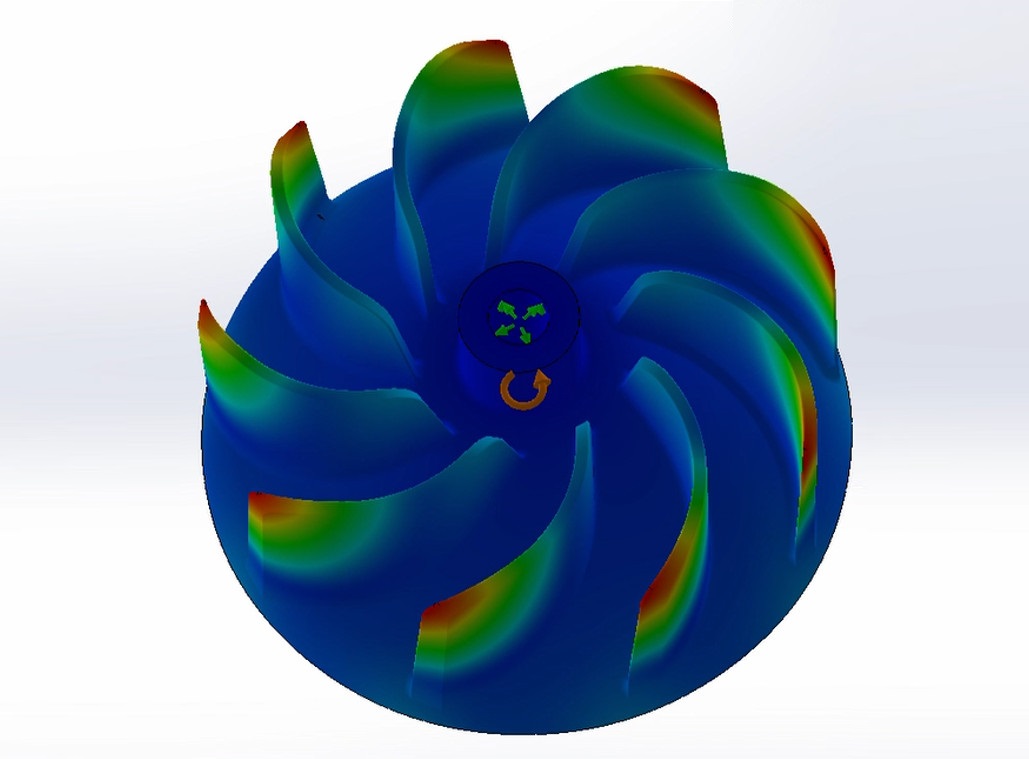

CFD (Computational Fluid Dynamics) Simulation:

Skills in modeling and simulating fluid flows to optimize aerodynamic and thermal design.

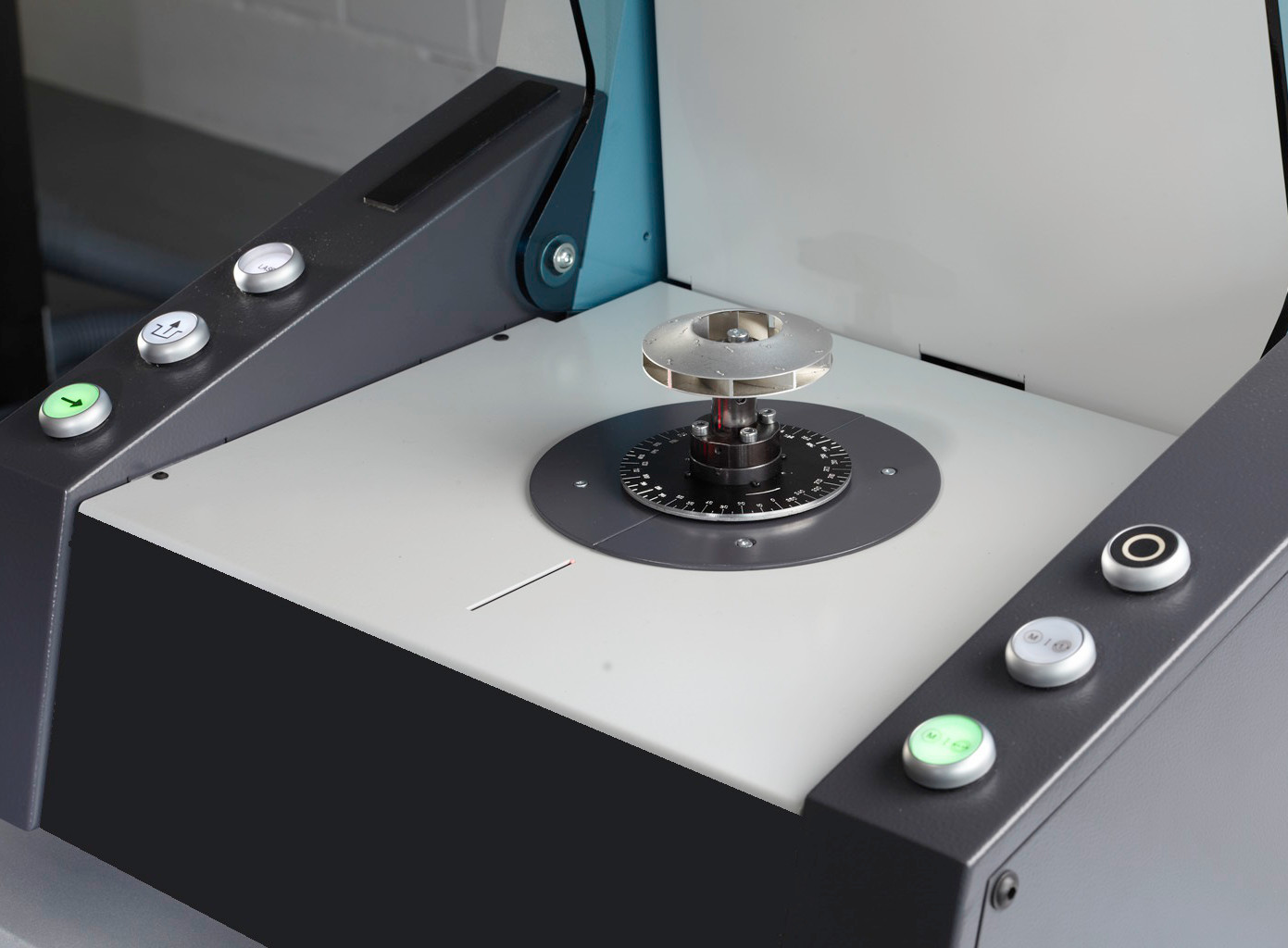

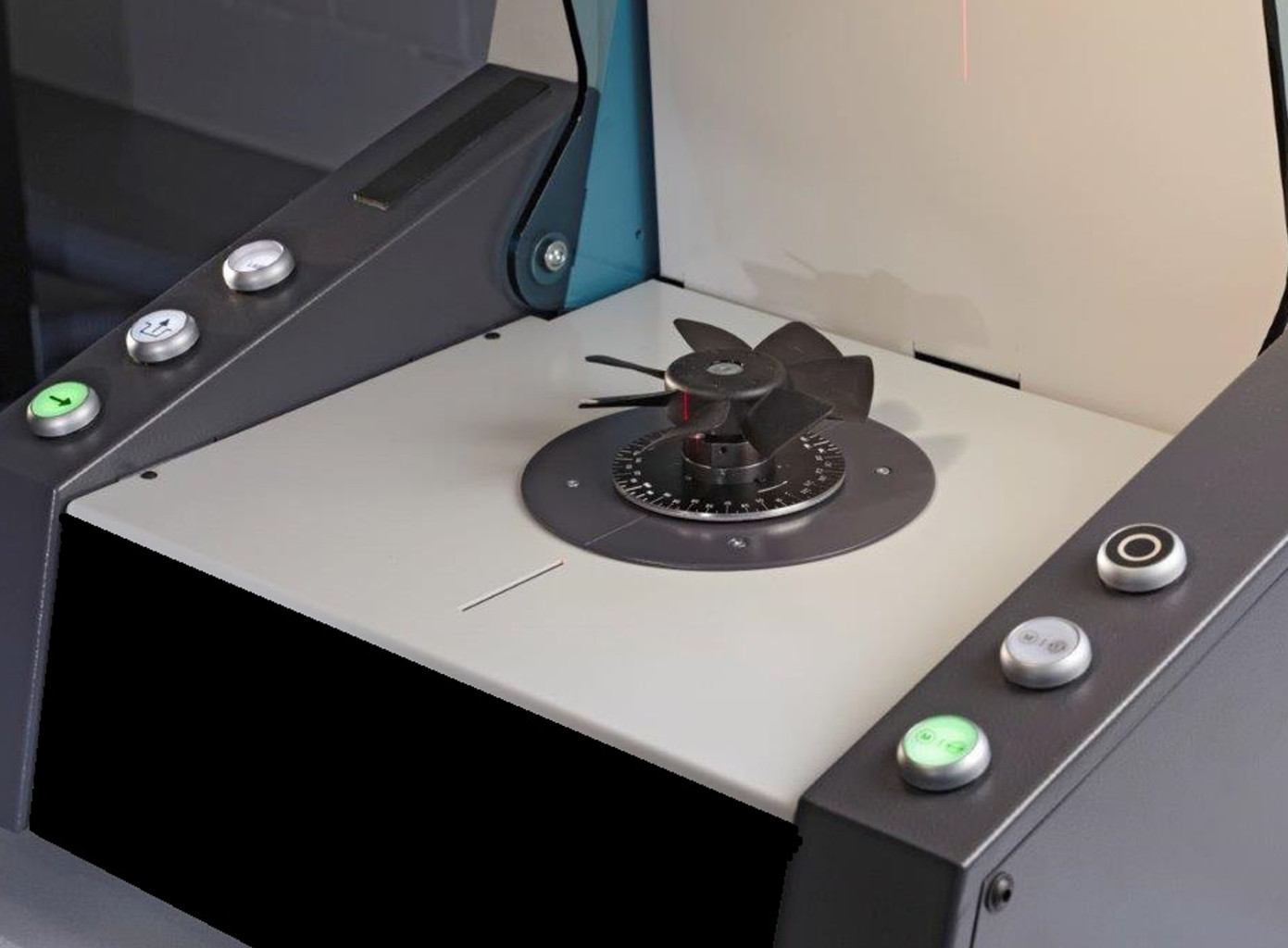

Balancers

The balancing machines we use are of absolute precision, thanks to their advanced technology they ensure repeatability of measurement of the imbalance, these instruments are able to measure the imbalance and allow to optimize the balancing operations of rotors of different sizes and weights, according to the international standards DIN EN ISO/IEC 17025

This allows extremely precise balancing to be performed, minimising the risk of failure and improving the reliability of rotating components.

Humidification

POST molding

The humidification cycle is documented by a graph showing the various processing phases, which we usually attach to the customer, where the time, degrees and humidity reached are specified.

–